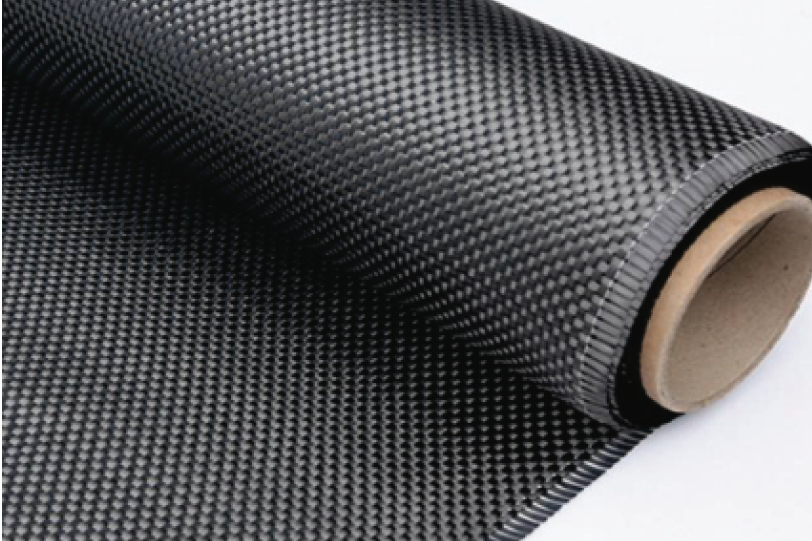

Bidirectional Carbon Fiber Fabrics

Products

- Unidirectional Carbon Fiber Fabrics

- Bidirectional Carbon Fiber Fabrics

- Carbon Fiber Plate For Reinforcement

- Carbon Fiber Rebar (CFRP)

- Carbon Fiber Laminates (CFRP)

- Chopped Carbon Fibre Strands

- Carbon Fiber Powder

- Epoxy Resin For Fabrics

- Prepreg Carbon Fiber Fabric

- Chemical Anchoring & Rebar Grouting Epoxy

- Epoxy Putty For Surface Preparation

Get In Touch With Us

+91 9702035271

Overview

Bidirectional carbon fibre fabric is a type of reinforcement material used in composites manufacturing. Carbon fibre is an extremely strong and lightweight material composed of thin fibres made mostly of carbon atoms.

Bidirectional carbon fibre fabric refers to a fabric where the carbon fibres are arranged in two primary directions: the warp and weft directions. In other words, the fibres run parallel to the length (warp) and width (weft) of the fabric. This arrangement provides strength and stiffness in both directions, making it ideal for applications where strength is required in multiple directions, such as in aerospace, automotive, sporting goods, and marine industries.

Properties

- High tensile strength: Resists stretching and withstands applied loads.

- Lightweight: Provides strength without adding significant weight to structures.

- Stiffness: Offers rigidity and maintains shape under stress.

- Corrosion resistance: Endures exposure to harsh environments without deterioration.

- Fatigue resistance: Withstands repeated loading cycles without weakening.

- Dimensional stability: Maintains structural integrity and shape over time.

- Electrical conductivity: Facilitates grounding and electromagnetic shielding.

- Thermal conductivity: Efficiently dissipates heat and withstands temperature fluctuations.

- Chemical inertness: Resists degradation from exposure to chemicals and solvents.

- Customizable: Allows for tailored reinforcement based on specific application requirements.

| No | Reinforcement Yarn | Weave Pattern | Fiber Count(10mm) | Weight(G/SQ.M) | Thickness(mm) | Width(mm) | ||

|---|---|---|---|---|---|---|---|---|

| Warp | Wept | Warp | Wept | |||||

| BD-F1KP120 | 1k | 1k | Plain | 9 | 9 | 120 | 0.12 | 100-1500 |

| BD-F1KT120 | 1k | 1k | Twill | 9 | 9 | 120 | 0.12 | 100-1500 |

| BD-F1KP140 | 1k | 1k | Plain | 10.5 | 10.5 | 140 | 0.14 | 100-1500 |

| BD-F1KT140 | 1k | 1k | Twill | 10.5 | 10.5 | 140 | 0.14 | 100-1500 |

| BD-F3KP160 | 3K | 3K | Plain | 4 | 4 | 160 | 0.16 | 100-1500 |

| BD-F3KT160 | 3K | 3K | Twill | 4 | 4 | 160 | 0.16 | 100-1500 |

| BD-F3KP180 | 3K | 3K | Plain | 4.5 | 4.5 | 180 | 0.18 | 100-1500 |

| BD-F3KT180 | 3K | 3K | Twill | 4.5 | 4.5 | 180 | 0.18 | 100-1500 |

| BD-F3KP200 | 3K | 3K | Plain | 5 | 5 | 200 | 0.20 | 100-1500 |

| BD-F3KT200 | 3K | 3K | Twill | 5 | 5 | 200 | 0.20 | 100-1500 |

| BD-F3KP220 | 3K | 3K | Plain | 5.5 | 5.5 | 220 | 0.22 | 100-1500 |

| BD-F3KT220 | 3K | 3K | Twill | 5.5 | 5.5 | 220 | 0.22 | 100-1500 |

| BD-F3KP240 | 3K | 3K | Plain | 6 | 6 | 240 | 0.24 | 100-1500 |

| BD-F3KT240 | 3K | 3K | Twill | 6 | 6 | 240 | 0.24 | 100-1500 |

| BD-F6KP280 | 6K | 6K | Plain | 3.5 | 3.5 | 280 | 0.28 | 100-1500 |

| BD-F6KT280 | 6K | 6K | Twill | 3.5 | 3.5 | 280 | 0.28 | 100-1500 |

| BD-F6KP320 | 6K | 6K | Plain | 4 | 4 | 320 | 0.32 | 100-1500 |

| BD-F6KT320 | 6K | 6K | Twill | 4 | 4 | 320 | 0.32 | 100-1500 |

| BD-F6KP360 | 6K | 6K | Plain | 4.5 | 4.5 | 360 | 0.36 | 100-1500 |

| BD-F6KT360 | 6K | 6K | Twill | 4.5 | 4.5 | 360 | 0.36 | 100-1500 |

| BD-F12KP320 | 12K | 12K | Plain | 2 | 2 | 320 | 0.32 | 100-1500 |

| BD-F12KT320 | 12K | 12K | Twill | 2 | 2 | 320 | 0.32 | 100-1500 |

| BD-F12KP400 | 12K | 12K | Plain | 2.5 | 2.5 | 400 | 0.40 | 100-1500 |

| BD-F12KT400 | 12K | 12K | Twill | 2.5 | 2.5 | 400 | 0.40 | 100-1500 |

| BD-F12KP480 | 12K | 12K | Plain | 3 | 3 | 480 | 0.48 | 100-1500 |

| BD-F12KT480 | 12K | 12K | Twill | 3 | 3 | 480 | 0.48 | 100-1500 |

| BD-F12KP560 | 12K | 12K | Plain | 3.5 | 3.5 | 560 | 0.56 | 100-1500 |

| BD-F12KT560 | 12K | 12K | Twill | 3.5 | 3.5 | 560 | 0.56 | 100-1500 |

| BD-F12KP640 | 12K | 12K | Plain | 4 | 4 | 640 | 0.64 | 100-1500 |

| BD-F12KT640 | 12K | 12K | Twill | 4 | 4 | 640 | 0.64 | 100-1500 |

Success Stories

Switching to bidirectional carbon fibre fabrics has transformed our reinforcement process. Exceptional strength, lightweight design, and versatility deliver durability, improved load-bearing, and resilience. Elevate your projects with these fabrics!

1

1

Our values

Determined to cultivate long-lasting client relationships, grounded in fairness and excellence across all aspects of our operations. Our dedication ensures unparalleled satisfaction and trust.

Quality Assurance

Close Coordination

Customer Satisfaction

Epoxy Putty For Surface Preparation

Chemical Anchoring & Rebar Grouting Epoxy

Prepreg Carbon Fiber Fabric

Epoxy Resin For Fabrics

Carbon Fiber Powder

Main Application

- Aerospace: Used in fuselage and rudder reinforcement for aircraft.

- Sports Equipment: Reinforces automobile parts, fish poles, baseball bats, sleds, speedboats, badminton rackets, and more.

- Industry: Strengthens engine components, reinforced concrete structures, air blower vanes, and drive shafts.

- Fire Protection: Utilised in the production of fireproof clothing for military, firefighters, steel plants, and other fire-prone environments.